November 28, 2011

Fuji Xerox Develops Woody Biomass Plastic

Keywords: Environmental Technology Manufacturing industry

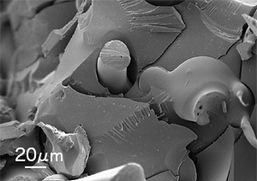

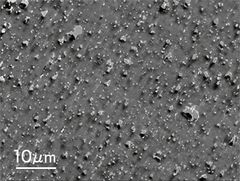

Before (left) and after (right) introducing the technology described in the article

Copyright Fuji Xerox Co.

Fuji Xerox Co. of Japan, part of the Fujifilm* group, announced on September 14, 2011, that they had developed materials and parts made of wood-derived, inedible biomass plastic, and obtained a Biomass-Pla (BP) Logo certified by Japan BioPlastics Association. This new biomass plastic is the first of its kind in the copier/printer industry.

*A diversified Japanese enterprise engaged in manufacturing, imaging, information and document solutions.

The new bioplastic, made of cellulose from woody resources, has plant-derived constituents that comprise approximately 40 percent of the total weight, in place of oil resources. Corn-based polylactide, a well-known bioplastic, has been widely used as a substitute in synthetic plastics. Unlike polylactide, however, inedible woody materials do not pose food issues. Moreover, as they are commonly available around the world, carbon-dioxide emissions caused by transportation can also be reduced.

A unique technology to optimally mix cellulose and oil-based constituents ensures molding flexibility and fluidity. The weld strength required of the substance used for injection molding is even superior to oil-based acrylonitrile-butadiene-styrene resin, or ABS resin.

Fuji Xerox developed the bioplastic under two partnerships. They conducted, jointly with Fujifilm Corp., basic research to add essential properties such as moldability to cellulose, while they developed, with Daicel Polymer, a major thermoplastics maker, technologies for dyeing the plastic for use in mechanical parts, as well as for mass production, to confirm practical applications for the new material. Fuji Xerox further aims to enhance the environmental friendliness and properties of the material, reduce costs, and broaden the scope of its application.

MGC Develops New Heat-resistant Bio-based Polyamide Resin (Related JFS article)

http://www.japanfs.org/en/pages/030548.html

NEC Develops New Bioplastic with High Plant Composition, Durability and Stable Supply (Related JFS article)

http://www.japanfs.org/en/pages/030405.html

Fuji Xerox Develops Enhanced Biomass Plastic (Related JFS article)

http://www.japanfs.org/en/pages/026861.html

Posted: 2011/11/28 06:00:15 AM

Reference

Fuji Xerox Develops Inedible Woody Biomass Plastic Reducing the Use of Petroleum Resources by 40 Percent

http://www.fujixerox.co.jp/eng/company/headline/2011/0914_bio_plastic.html

Related

"JFS Newsletter"

Related

"Popular Articles"

- New Nano-Bubble Technology May Help Dissolve Sludge and Improve Water Quality

- Japanese Firm Begins Development of Tidal Power Generation System

- Small Hydropower Generation System Developed for Use in Seawater, Weight Cut by Half

- Constructed Wetland Facility Established by Japanese University Purifies Livestock Farming Drainage

- Toyota CRDL Succeeds in World's First Artificial Photosynthesis Using only Water and CO2